HP SitePrint – Robotic Printing Technology

Revolutionize Construction Site Layouts with Breakthrough Efficiency

UNPARALLELED:

Accuracy, Speed, and Efficiency

In the fast-paced world of construction, precision and efficiency are critical. The HP SitePrint Robotic Layout Printer is an industry game-changer—an autonomous, cutting-edge solution designed to streamline site layouts, enhance accuracy, and dramatically boost productivity.

By leveraging HP’s world-class printing technology and robotics expertise, SitePrint automates layout processes, minimizing human error, reducing labor costs, and allowing construction teams to focus on building rather than marking.

Performance & Productivity

Improve layout productivity up to ten times compared to traditional chalk-line layout.

Autonomous printing with obstacle avoidance and HP Smart Navigation System.

Print detailed information with precision, ensuring smooth installations.

Compact design that fits in a portable case for effortless transport.

HP SitePrint: Step-by-Step Workflow

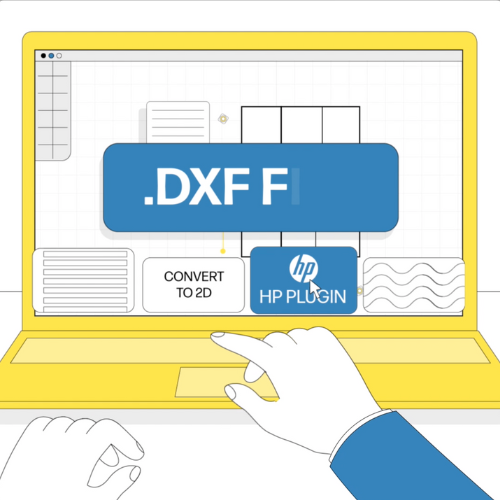

Step 1

Prepare a 2D ‘Robot Ready’ File

Our HP SitePrint-certified specialists provide training so your team can convert BIM models for robotic layout. Using the SitePrint plugin in AutoCAD or Revit, users define printable elements, obstacles, and control points. The plugin then processes the model into a robot-ready 2D format. For clients opting to outsource this step, Site Precision partners with a provider specializing in SitePrint file preparation.

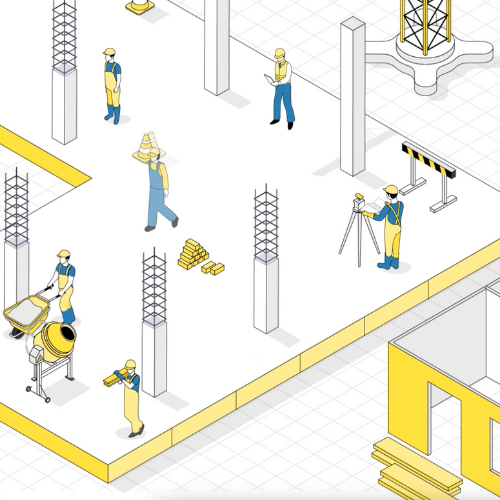

Step 2

Prepare the Jobsite

HP SitePrint operates under jobsite conditions similar to manual layout. For maximum efficiency, clear as many obstacles as possible from the layout area. No need for excessive cleaning since the robot will print on dusty and damp surfaces. Thanks to its rugged design and built-in tilt compensation sensors, rough and uneven surfaces are also no challenge for SitePrint.

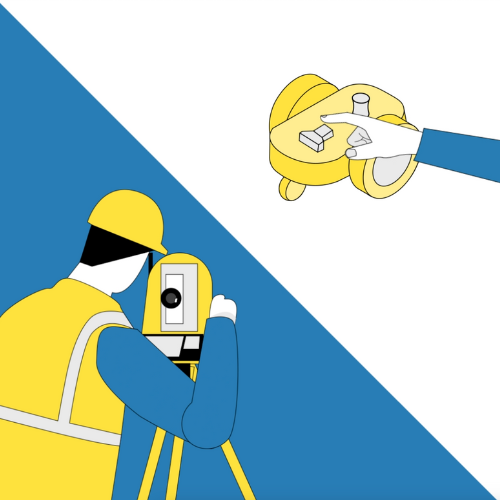

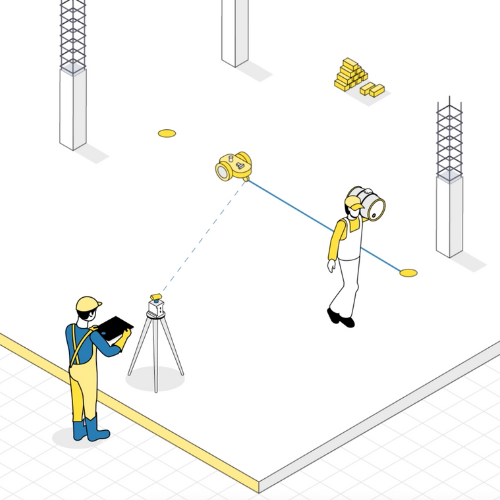

Step 3

Perform Setup with Robotic Total Station

Use a robotic total station to measure at least two control points using prisms or reflectorless mode—this is identical to traditional RTS setup. After measuring, the operator reviews the residuals to ensure accuracy. Once verified, lock the RTS onto the prism mounted on the SitePrint, and you’re ready to print.

Step 4

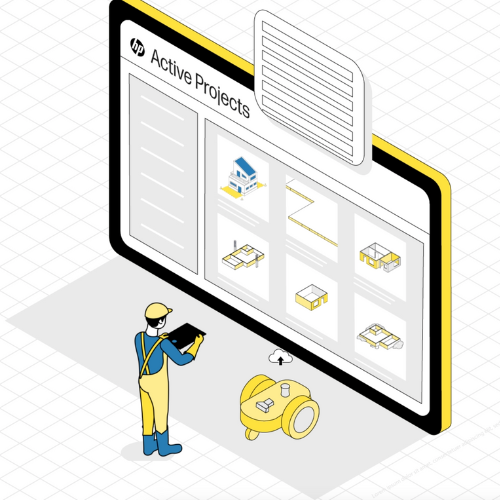

Operator Executes Layout Using the HP SitePrint User Interface

HP SitePrint’s UI runs on any device with WiFi and a web browser. Through the user-friendly interface, operators can select print elements and manually add any unexpected obstacles. When ready, simply press ‘Print’, and let the robot go to work. A handheld joystick allows for manual override when needed.

Step 5

End-to-End Management

HP SitePrint adds value on-site and in the office through its cloud-based software. Before printing, users can upload drawings to a simulator for accurate layout time and cost estimates. During printing, real-time cloud connectivity provides progress updates, performance metrics, and access to support resources—streamlining the entire workflow.

Versatile Surface Printing

Equipped with specialized ink from HP, SitePrint can print on various surfaces including rough concrete, tarmac, plywood, formwork, and vinyl. With permanent and semi-permanent ink options, our ink portfolio adjusts to different project requirements.

Enhanced Jobsite Safety

With built-in safety stop technology, HP SitePrint operates autonomously while preventing falls, collisions, and other hazards, enabling it to work on almost any construction site.

Cloud-Based Layout Management

The HP SitePrint Cloud software enhances communication and transparency between office staff and field crews. Office teams can seamlessly upload updated file versions to the cloud, ensuring layout crews always have the latest information. Additionally, the software enables layout cost prediction, tracks costs and productivity, and monitors progress from start to completion, providing real-time insights that were never possible before.

Trusted by Pros Like You

Transform Your Construction Workflow

HP SitePrint is not just a tool—it’s a competitive advantage. By improving layout speed, precision, and jobsite efficiency, it enables construction firms to reduce costs, prevent errors, and meet project deadlines with confidence.

Whether you’re working on commercial buildings, healthcare facilities, or industrial projects, HP SitePrint is the future of construction layouts.

Precision In Every Project

Alex

Layout Foreman, Kent Companies

“10/10 excellent service — fast and friendly. Training service was top notch all around. Would recommend to anyone looking for a professional measurement system that is accurate, easy to use, and most importantly, not overpriced.”

Joshua Pittsley

Owner, Lakeshore Construction

“From my first phone call to Brian inquiring about new equipment to trouble shooting issues with Christian, the crew at Site Precision is there for you. Thank you for all the help throughout the years.”

Jeremiah Coyle

Training Instructor, Michigan Regional Council of Carpenters Training Center

“Site Precision has been great to do business with. Christian and Mario have been very helpful with setting us up with the right instruments and offering training to get us started.”

Bryan Edwards

Executive Director of Operations, Safety, Quality Control, Ritsema Associates

“Site Precision’s service and support have been incredible. Since day one of purchasing our total station and layout robot from them they have been there to help us with training, implementation, and follow-up support anytime our field crews have questions.”

Lance Zuidema

Foreman, Bunker Concrete Construction

“Amazing tools and great guy to show you how to work it. Definitely wouldn’t of learned so quickly without their guidance!”

Nick Bongero

Foreman, Turner Brooks

“Very thorough training, excellent representatives and an excellent product!”

HP SitePrint FAQs

What is an HP SitePrint construction layout printer?

The HP SitePrint is an automated construction layout device that prints digital plans directly onto the job site floor, significantly speeding up the process of marking walls, MEP, industrial machinery, and much more.

Can I rent HP SitePrint?

How fast can HP SitePrint layout?

The HP SitePrint navigates between each print element at 2.30 feet per second and prints an average of 936 linear feet per hour. For MEPF trades, SitePrint prints 200 points per hour on average (includes point and text label). However, actual print speed may vary depending on the size and complexity of the project.

Is it smart enough to avoid obstacles?

What can it print?

Who is using HP SitePrint?

What are the key benefits of robotic layout?

Why should I purchase HP SitePrint through Site Precision?

How many people are required to operate HP SitePrint?

Can HP SitePrint print over difficult surfaces like rough concrete?

Yes. It can overcome concrete roughness or any other obstacles up to 2 inches thick. Furthermore, the robot can keep printing accurately even when tilting.

How long does the ink last?

How does it work on the job site?

How does the AutoCAD prep work?

Do I need to be an AutoCAD expert?

Can I prepare my files in Revit?

See Precision in Action - Book A Demo

Experience the power of advanced robotic layout solutions firsthand. Our experts will walk you through the best tools for your needs, helping you improve accuracy, efficiency, and project outcomes.

Discover how robotic total stations, HP SitePrint, and construction lasers can transform your workflow.